EN

Translate:

EN

EN

Translate:

EN

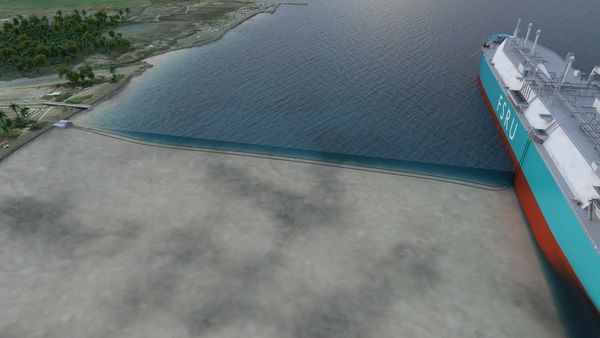

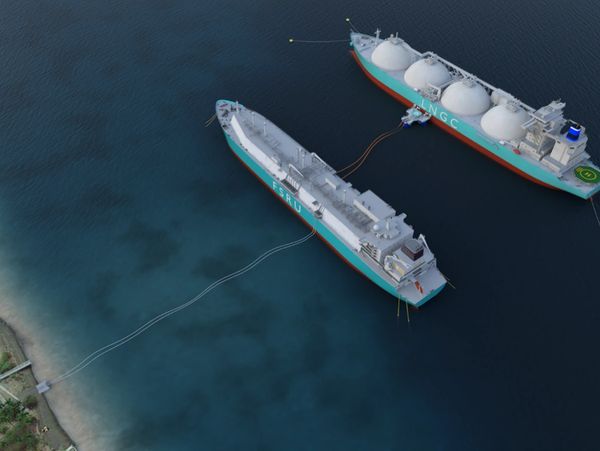

LNG import into new onshore terminals has never been quicker nor easier—jettyless LNG transfer allows for rapid and cost-effective solution for LNG transport from offshore facilities to receiving terminals.

The Canaf Energy jettyless LNG transfer system solutions leverage traditional marine infrastructure, existing LNG transfer methods and is also configured for scalability and compatibility with a wide range of FSUs and FSRUs. The jettyless scope accelerates consumer access to natural gas and other fluids such as ammonia and hydrogen, in a cost-effective and agile manner.

The jettyless field-proven system makes LNG accessible to locations with a lead time of 6-9 months for a new build, with chartering options to suit short-term demand. With a modular system, the jettyless IQuay solution is flexible to energy demand, and can operate in busy port and harbour areas without needing to build new port infrastructure.

The system consists of a single adaptable plug-and-play platform, the IQuay, a jettyless solution which universally connects to any vessel in any port, and flexible cryogenic floating hoses which connect the platform to the onshore terminal.

-p-1080.png/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:600,cg:true)

The IQuay enables transfer of LNG between a vessel and storage facilities and is fully qualified by DNV GL.

Distance from shore

50 - 800 m

Environment

Sheltered to harsh conditions

Flowrate

100 - 2,500 m3/h

Transfer lines

Floating cryogenic hoses

Carrier vessel size

1,000 - 266,000 m3

Design life

25 years

We have leveraged on the Standard IQuay qualified design to develop solutions for large scale LNG import and export between ship & shore.

Distance from shore

50 - 800 m

Environment

Sheltered to harsh conditions

Flowrate

2,500 - 12,000 m3/h

Transfer lines

Floating cryogenic hoses

Carrier vessel size

Up to 266,000 m3

Design life

25 years

Shipping LNG overseas is by far the most common way to transport natural gas in liquid form. When LNG plants and fields are situated in remote areas, transportation of LNG by ship is often the preferred, or perhaps even the only, alternative for transporting natural gas. Therefore, LNG ships makes a key link in the LNG value chain, enabling transportation of gas between the liquefaction plant and regasification site.

Shipping LPG overseas is by far the most common way to transport natural gas in liquid form. When LPG plants and fields are situated in remote areas, transportation of LPG by ship is often the preferred, or perhaps even the only, alternative for transporting natural gas. Therefore, LPG ships makes a key link in the LPG value chain, enabling transportation of gas between the liquefaction plant and regasification site and/or Loading ISO Tank Containers Depot.

Shipping BLCO overseas is by far the most common way to transport crude oil in bulk form. When crude oil refinery plants and fields are situated in remote areas, transportation of BLCO by ship is often the preferred, or perhaps even the only, alternative for transporting crude oil. Therefore, BLCO ships makes a key link in the BLCO value chain, enabling transportation of oil between the crude oil refinery plant and final petrochemicals refinery site.

Shipping LPFO overseas is by far the most common way to transport LPFO in bulk form. When crude oil refinery plants and fields are situated in remote areas, transportation of LPFO by ship is often the preferred, or perhaps even the only, alternative for transporting low pour fuel oil. Therefore, LPFO ships makes a key link in the LPFO value chain, enabling transportation of oil between the crude oil refinery plant and heating site.

Copyright © 1997 - 2024 Canaf Petro-Chemicals Refinery™ (CPCR) - All Rights Reserved.

This website uses cookies. By continuing to use this site, you accept our use of cookies.